Kuaike Precision Alloy is one of the leading ceramic materials processing technology innovators, committed to product quality improvements and cutting-edge innovations for wholesale purchase. Centered around innovation and with years of experience in the industry, our organization is known for its quality products within the ceramic sector.

Smart Kitchen Knife Processing Technique for Commercial Buyers

Kuaike Precision Alloy is committed to leading the development of ceramics processing technology. We also reinvest in R&D to offer innovative solutions that would serve a growing wholesale customer. Automation is one of the most important developments that we've utilized in our manufacturing. Through automation, we can manage the process and enhance efficiency while maintaining a consistent product. This enables us to deliver the high-volume orders without sacrificing on the quality or performance.

In addition, our company has adopted a digital transformation to improve the ceramic process. Using integrated digital tools and systems, it's possible to increase our production capability, decrease lead times for short-term decisions and adjust speedily when market conditions change. We have for instance, deployed a Manufacturing Execution System (MES) and the Supervisory Control and Data Acquisition (SCADA) to track our shop floor manufacturing processes in real time. These are what allow us to make data-based decisions, know where we can do better and be improving.

Besides, smart factory ideas are also adopted by Kuaike Precision resistance alloy material in order to build a more interconnected and efficient workspace. We allow us to be more proactive because they can use IOT devices and AI. Our smart factory projects also enable us to supply bespoke solutions to wholesale customers, which means we can respond quickly and accurately to their individual needs. From our state-of-the-art factory, using smart technologies we guarantee that every ceramic product meets your highest standards, as well as fulfilling its functionality and adding value to your home.

Industry Changing Ceramic Processing Techniques – Anybody Doing Ceramics Should Learn This

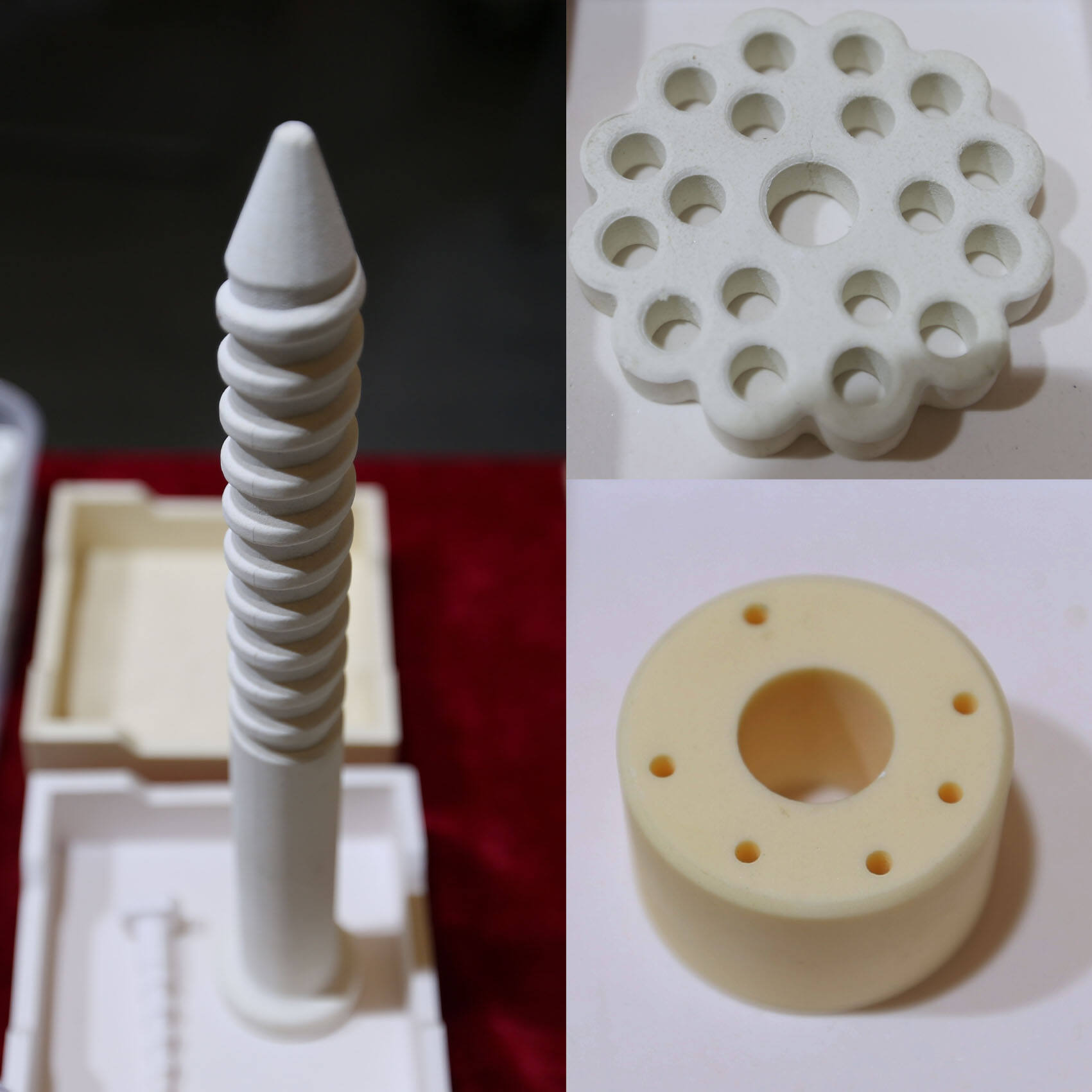

Kuaike Precision Alloy leads the way in revolutionizing ceramic processing technology. Ceramics have significantly sophisticated in terms of processing technology in recent years, which have led to the improvement of products dimensions and manufacturing productivity. Additive manufacturing methods, example, 3D printing, represent a notable advancement in ceramic processing technology. The process according to the invention makes it possible to form complex ceramic forms, which could not be made in this way before.

Another innovative development is the application of sophisticated materials and coatings that increase service life and performance for ceramic goods. These advanced materials are increasing the wear and corrosion resistance of ceramics, enabling their application in new industries. Further, advancements in manufacturing methods, including machining and sintering with tighter tolerances and improved surface finishes on the ceramic parts.

Ceramic Processing Technology and Its Impact on the Wholesale Market

Kuaike Precision is changing the face of the wholesale /B2B industry with revolutionary new ceramic processing techniques. As a result of these developments, products with high quality affordable price range are also offered to wholesale businesses. Custom-engineering ceramic products has allowed wholesalers to take advantage of competitive pricing and fast delivery.

In addition, the development of ceramic products has enabled trading companies to diversify themselves by penetrating into niche markets and extend product range. For instance, the increasing employment of advanced ceramics within the aerospace and medical industry has generated a need for custom made ceramic components based on precision manufacturing. With production of ceramics fully under the microscope in more and more businesses, wholesaling is no different as ever-higher expectations are increasingly being placed upon it.

Why Wholesale Business Needs Ceramic Processing Technology at Best

Wholesale ceramic processing technology is one of the musts for those looking to break through in the market today. The speedy production of quality ceramic products is essential for meeting the demands from customers and ensuring a reputable product in the industry. Wholesalers can enhance the quality of product properties and offerings, cut better deals with manufacturers to reduce production cost, and maximize profits by making investments on advanced ceramics processing technologies.

Furthermore, ceramic materials have some extraordinary properties, including high strength, thermal resistance and electrical insulation, so that they are suitable for many uses. With the integration of ceramic products into its inventory, a wholesale company may gain new customers and enter markets it has not have been able to reach previously. All in all, ceramic processing technology really changes the game for wholesale firms: giving them what they need to succeed in a cut-throat market.

EN

EN

AR

AR

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

IW

IW

ID

ID

SR

SR

SL

SL

UK

UK

VI

VI

HU

HU

MT

MT

TH

TH

TR

TR

AF

AF

MS

MS

GA

GA

AZ

AZ

MN

MN

MY

MY

KK

KK

UZ

UZ

KY

KY

BN

BN