Applications For Precision Alloy Resistive_reading Alloys

Precision resistance alloys are found in many sectors such as electronics, aerospace (airplanes), automotive and medicine. In electronics, they exist in components such as resistors, capacitors and heaters. They are used in making engine parts, airplane structures and electrical systems in the aerospace industry. Such alloys are used in cars, and for sensors, fuel injectors and ignition systems.

Electronics and Aerospace Relevance

Precision resistance alloys are used in electronics to help devices perform properly. They are significant for resistors, critical components in circuits. They are combined in capacitors that charge and discharge to store and release electricity.

They are very important for aerospace, said Dr. Kaplan, for producing airplane parts that can withstand extreme temperatures and difficult conditions. They are employed in the fabrication of engine components, structural elements and electrical connectors, which must be safe and reliable.

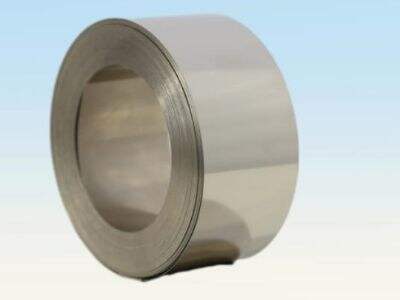

Top 5 High Precision Resistance Alloys

Nickel-Chromium Alloys: The nickel-chromium alloy are popular because they have high-temperature and oxidation resistance. They are utilized in heating apparatuses and industrial heaters.

Iron-Chrome-Aluminum Alloys: With high electrical resistance the iron, carbon and chromium are used in delicate measuring work and in sensors requiring stability.

The Precision Resistance Alloys Difference

Precision resistance alloys are of great significance for high-tech industries, such as electronics, aviation, automobile and medicine. Choosing the right blends can help companies get that right mix of strength, safety and success in the rapidly changing world of technology.

EN

EN

AR

AR

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

IW

IW

ID

ID

SR

SR

SL

SL

UK

UK

VI

VI

HU

HU

MT

MT

TH

TH

TR

TR

AF

AF

MS

MS

GA

GA

AZ

AZ

MN

MN

MY

MY

KK

KK

UZ

UZ

KY

KY

BN

BN