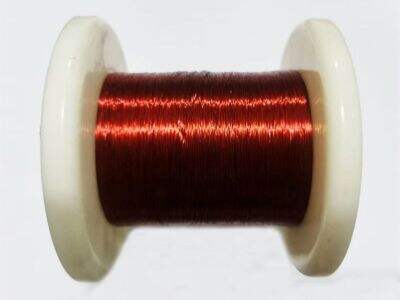

שפכי פוליאוריטן, פוליאסטר ופוליאימיד משמשים בתעשייה כדי לכסות חומרים שונים נגד קורוזיה, בلى או מתח. לכל סוג שפכין יש יתרונות משלו ובעיות יישום טיפוסיות שעל מקצבים מקצועיים להתחשב בהן בעת בחירת השפכין המתאים לשימוש מסוים. Kuaike Precision Alloy היא יצרנית מומחית של איכות גבוהה תיל נחושת מעופף לשימושים תעשייתיים שונים.

שפכי פוליאוריטן, פוליאסטר ופוליאימיד

שימיות פוליאורטן ידועות בקשיותן הרבה, עמידותן בפני שחיקה, שמן ופירוק כימי, וביכולתן לעמוד בפני חשיפה ממושכת לאור ללא התכה. תכונות אלו הופכות אותן למתאימות במיוחד לשימוש בחוץ או בסביבות פנימיות קשות כמו חנויות תיקון רכב. הן מציעות גמישות נוספת, המונעת סדקים או התרסקות של החומר המוכסה. לעומת זאת, שימיות פוליאסטר מוערכות בעבור הקשיות והעומס המצוינים שלהן, ושימוש בהן נעשה באזורים עם תנועה גבוהה כמו רצפות תעשייתיות, מכונות ומתקנים. שימיות פוליאמיד מוערכות בעבור עמידותן בטמפרטורות גבוהות ולכן הן אידיאליות לשימושים הדורשים הגנה מפני טמפרטורות גבוהות, כמו רכיבי תעופה, בידוד חשמלי, מנועים. יתר על כן, לשימיות פוליאמיד יש עמידות כימית ואפיוני בידוד חשמלי יוצאי דופן, הנדרשים במפעלים תעשייתיים רבים.

בעיות נפוצות בשימיות פוליאורטן, פוליאסטר ופוליאמיד

עמידות בבהמה היא יתרון מיוחד מכיוון שארוגלן פוליאורית'נים, כאשר הם נחשפים לשמש במהלך זמן קצר יחסית, עלולים להפוך לצהובים ולכן לפגוע במראה של השטח המוכסה. ייתכן גם שיידרשו תחזוקה רבה יותר ושכבות נוספות כדי לשמור על עמידותם לאורך זמן. אם כי ארוגלן פוליאסטר הם עמידים ביותר, הם עלולים להיות קשים להחלת באופן אחיד בגלל הצמיגות הגבוהה שלהם; הסיום עלול להפוך למ kếtס או לא אחיד אם לא יטופלו כראוי. הם גם יכולים להישבר ולצנח בקלות במקרה של פגיעה, ולכן נדרשת חזרה על הצביעה כדי לשמור על המראה החדש של הכיסוי. ארוגלן פוליאימיד עלולים להיות יקרים יחסית בייצור והחלתם, במיוחד לחלק מהיישומים, גם אם ידוע שהם עמידים בפני טמפרטורות גבוהות של שימוש. בנוסף, הצבעים המוגבלים הזמינים למכירה עלולים להגביל אותם לפרויקטים מסוימים שיש להם מראה או צורך בעיצוב רצוי. לסיכום, יש להבין את היתרונות הפוטנציאליים ואת הקשיים הנפוצים בשימוש בארוגלן פוליאורית'ן, פוליאסטר ופוליאימיד בעת בחירת ציפויים למטרות תעסוקתיות כדי להשיג ביצועים מקסימליים וחיי שירות ארוכים.

למה הביקוש סיטונאי לספוגים פוליאימידיים מתרחב?

חוטי נחושת מסופגים בפוליאימיד זוכים להכרה מהירה בתעשיית הסיטונאות, בזכות עמידותם הגבוהה בחום ועמידותם הרבה. ספוגים אלו של Kuaike Precision Alloy תיל אמפולג' עם חוט אלומיניום עמידים בחום ויכולים לשאת טמפרטורות גבוהות, מה שחשוב לשימוש תעשייתי. לסרטים מסופגים בפוליאימיד יש גם עמידות כימית מצוינת, והם מתאימים לסביבות שונות. העמידות היוצאת דופן שלהם גם בתנאים הקיצוניים ביותר מבדילה אותם מסוגי ספוגים אחרים, וmakes them the ideal option for wholesale buyers searching for long lasting, proven enamel coating products.

ספוג פוליאורטן לעומת פוליאסטר ופוליאימיד

שימויות בידוד מפוליאוריטן משלבות תכונות פיזיות וכימיות טובות של שימויות פוליאסטר עם גמישות גבוהה לסף הבסיס של שימויות פוליאימיד. הן רצויות בשל הדבקות הטובה שלהן ל סוגי משטחים שונים ולעמידות בפני שחיקה ומכה. ידוע גם ששימויות פוליאוריטן שומרות היטב על צבעיהן, ולכן ניתן להשתמש בהן ביישומים הדורשים מראה אסתטי מסוים. הנוסחה של שימויות פוליאוריטן בכפפות מצופות מספקת דקיות עילאית המאפשרת אפילו כיפוף ומתיחה של היד ללא סדקים או התרוקנות, ומספקת אפשרות רב-תכלית לשימושים תעשייתיים רבים במכירה בجملة.

השימויות הטובות ביותר לשימושים תעשייתיים במכירה בجملة

לשימושים תעשייתיים במכירה סיטונאית, שפכים פוליאימיד הם לעיתים קרובות הבחירה המועדפת בשל עמידותם הגבוהה בפני חום ובריאות. השפכים מספקים עמידות בפני טמפרטורות גבוהות וסביבות אגרסיביות, מה שהופך אותם למתאימים במיוחד ליישומים תעשייתיים קשיחים. יתר על כן, לשפכי פוליאימיד יש עמידות טובה לכימיקלים; ולכן הם שומרים על תכונותיהם גם כשנמצאים במגע עם חומרים כימיים שונים. כאשר קונים סיטונאיים צריכים מוצר ציפוי עמיד וארוך-טווח המסוגל לעמוד בתנאים קיצוניים, הם יודעים להסתמך על הפוליאימיד תיל אמברוז שזמין מחברת Kuaike Precision Alloy.

EN

EN

AR

AR

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

IW

IW

ID

ID

SR

SR

SL

SL

UK

UK

VI

VI

HU

HU

MT

MT

TH

TH

TR

TR

AF

AF

MS

MS

GA

GA

AZ

AZ

MN

MN

MY

MY

KK

KK

UZ

UZ

KY

KY

BN

BN