အီမေလ်ဝိုင်ယာ၏ စွမ်းဆောင်ရည်ကို မြှင့်တင်ရန်၊ ကာကွယ်ပေးရန်နှင့် လျှပ်စစ်ကို ပိုမိုကောင်းမွန်စွာ စီးဆင်းနိုင်ရန်အတွက် ကာလှယ်ပေါ်လီမာသည် အဓိကအချက်တစ်ခုဖြစ်သည်။ အီမေလ်ဝိုင်ယာသည် မည်သည့်အသုံးချမှုတွင်မဆို အဆင့်မြင့်စွမ်းဆောင်ရည်ဖြင့် ကြာရှည်ခံစေရန် အရည်အသွေးမြင့် ကာလှယ်ပေါ်လီမာထုတ်ကုန်များ၏ အရေးပါမှုကို ကျွန်ုပ်တို့ နားလည်ပါသည်။

အလွှာကာပေးထားသော ထုတ်ကုန်များ၏ အမျိုးအစားများကို လက်ကားရောင်းချရန် ရရှိနိုင်ပါသည်။

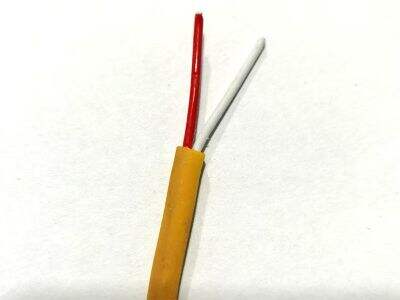

အီမယ်ဝိုင်ယာအတွက် အခြေကာကွယ်ရေး ပေါင်းစပ်ပစ္စည်းသည် အပူခံနိုင်ရည်၊ ဓာတုပစ္စည်းခံနိုင်ရည်နှင့် ကပ်လိုက်နိုင်မှု စသည့် ဂုဏ်သတ္တိများ ပိုင်ဆိုင်ထားရန် လိုအပ်ပါသည်။ Kuaike Precision Alloy သည် အရည်အသွေးကောင်းများပြီး ဈေးနှုန်းချိုသာသော အခြေကာကွယ်ရေး ပေါင်းစပ်ပစ္စည်းများကို စုလုံးဝယ်ရောင်းပေးသည့် ထူးချွန်သော ထုတ်လုပ်သူဖြစ်ပါသည်။ ကျွန်ုပ်တို့၏ စီရမစ် သာမိုကပယ်လ် အငြိတ်ခံ အပူချိန်မြင့်မားခြင်း၊ ပြင်းထန်သော လည်ပတ်မှုအခြေအနေများနှင့် ယန္တရားဆိုင်ရာ တိုက်ခိုက်မှုများကို ခံနိုင်ရည်ရှိစေရန် ဒီဇိုင်းထုတ်ထားပြီး အီမယ်ဝိုင်ယာ၏ ယုံကြည်စိတ်ချရသော စွမ်းဆောင်ရည်နှင့် ကောင်းမွန်သော ဝန်ဆောင်မှုသက်တမ်းကို ပေးစွမ်းနိုင်ပါသည်။ မော်တာများ၊ ထရန်စဖော်မာများ သို့မဟုတ် အခြားလျှပ်စစ်ပစ္စည်းကိရိယာများအတွက် အခြေကာကွယ်ရေး ပေါင်းစပ်ပစ္စည်းများ လိုအပ်ပါက သင့်လိုအပ်ချက်များနှင့် ကိုက်ညီသော ထုတ်ကုန်များကို ကျွန်ုပ်တို့ ပေးအပ်ပါသည်။

အီမယ်ဝိုင်ယာအတွက် အဆင့်မြင့် အခြေကာကွယ်ရေး ပေါင်းစပ်ပစ္စည်း

ကြွေရည်သုတ်ထားသော ဝါယာကြိုးအတွက် ထိပ်တန်း insulation coating ပေါ်တွင် သင့်လက်ကို ရယူရန် ခက်ခဲနိုင်သော်လည်း Kuaike Precision Alloy သည် အရည်အသွေးမြင့်ပြီး အကောင်းဆုံးစွမ်းဆောင်ရည်အတွက် စမ်းသပ်ထားသော ထိပ်တန်းအဆင့်သတ်မှတ်ထားသော ထုတ်ကုန်အမျိုးမျိုးကို ပေးဆောင်ထားသည်။ ကျွန်ုပ်တို့၏ insulation coatings များသည် ၎င်းတို့၏ထူးခြားသောအရည်အသွေး၊ အားကိုးနိုင်မှုနှင့် တာရှည်သက်တမ်းကြောင့် စက်မှုလုပ်ငန်းရှိ ကျွမ်းကျင်ပညာရှင်များမှ နှစ်သက်သဘောကျကြသည်။ ကြွေထည်ဝါယာကြိုးများအတွက် ကျွန်ုပ်တို့၏အကြံပြုထားသော လျှပ်ကာအကာအရံပစ္စည်းများကို ကျွန်ုပ်တို့၏တရားဝင်ဖြန့်ဖြူးသူများ၊ e-commerce ဆိုက်များနှင့် အရောင်းဝန်ထမ်းများထံမှ ရရှိနိုင်ပါသည်။ Kuaike Precision Alloy ဖြင့် သင်စျေးဝယ်သောအခါ၊ ၎င်းသည် မည်သည့်အပလီကေးရှင်းကိုအသုံးပြုသည်ဖြစ်စေ သင်၏ enameled wire ၏ထိရောက်မှုအမြင့်မားဆုံးကူညီပေးရန် အကောင်းဆုံး insulation coating ထုတ်ကုန်များကို သင်ရရှိထားကြောင်း သေချာစေနိုင်ပါသည်။

အိုင်ဆူလေးရှင်းဓာတ်ပါသော ဆေးသည် ဆေးကြိုး၏ စွမ်းဆောင်ရည်ကို မည်သို့သက်ရောက်မှုရှိပါသနည်း။

အျမြှုပ်ထားသောကြိုး၏ ဂုဏ်သတ္တိများကို ခြုံထားသည့် အလွှာက တိုက်ရိုက်သက်ရောက်မှုရှိပါသည်။ ၎င်းသည် ကြိုးကို ကာကွယ်ပေးပြီး ကြိုးများ တိုက်ရိုက်မခံနိုင်ခြင်း (သို့) လျှပ်စစ်ဓာတ်လိုက်ခြင်းမှ ကာကွယ်ပေးသည့် ကာကွယ်ရေးအဖြစ် ဆောင်ရွက်ပါသည်။ ကာကွယ်မှုများ မှန်ကန်စွာ မထုပ်ပိုးပါက ကြိုးသည် ပျက်စီးပြီး အသုံးမဝင်တော့ပါ။ အကျွေးထားသြိမ်း ထို့အပြင် ကြိုးသည် မပျက်စီးဘဲ ရှိနေစေရန် ကူညီပေးပြီး သတ္တုအတွင်းပိုင်းသည် အပူချိန်၊ စိုထိုင်းဆနှင့် ပျက်စီးစေသည့် ဒြပ်စင်များကို ခံနိုင်ရည်ရှိစေပါသည်။ ဤအချက်သည် အမှန်တကယ် အသုံးပြုမှုကို ပိုမိုကောင်းမွန်စေပြီး အျမြှုပ်ထားသောကြိုး၏ သက်တမ်းကို ရှည်လျားစေပါသည်။

ကြိုးပြုလုပ်ရာတွင် သင့်တော်သော ခြုံထားသည့်အလွှာကို မည်သို့ရွေးချယ်မည်နည်း။

ကြိမ်ထုတ်လုပ်မှုအတွက် အခြင်းပေးဖုံးအား ရွေးချယ်ခြင်း။ ကြိမ်၏ အသုံးပြုမှုလိုအပ်ချက်များဖြစ်သည့် အပူချိန်၊ ဗို့အားနှင့် ပတ်ဝန်းကျင်ဆိုင်ရာ အခြေအနေများပေါ်တွင် မူတည်၍ ကြိမ်၏ အခြင်းပေးမှုသည် ကွဲပြားပါသည်။ အသုံးပြုမှုအလိုက် ကွဲပြားသော ဂုဏ်သတ္တိများရှိသည့် အခြင်းပေးမှုအမျိုးအစားများစွာ ရှိပါသည်။ ဥပမာအားဖြင့် ပေါလီယူရီသိန်းဖြင့် ဖုံးအုပ်ထားသော ဖုံးသည် အပူဒဏ်ခံနိုင်ပြီး ပျော့ပြောင်းမှုရှိသောကြောင့် အပူချိန်မြင့်မားသော အခြေအနေများတွင် သင့်တော်ပါသည်။ ပေါလီအက်စတာ အခြင်းပေးဖုံးသည် ရေနှင့် ဓာတုပစ္စည်းများကို ခံနိုင်ရည်ရှိမှုကြောင့် ရွေးချယ်လေ့ရှိပါသည်။ အကောင်းဆုံး အခြင်းပေး ဗာနစ်ကို ရွေးချယ်သော ထုတ်လုပ်သူများသည် အမာရွတ်ဖြစ်နေသော ကြိမ်ကို အကောင်းဆုံးစွမ်းဆောင်ရည်ဖြင့် အကြာဆုံး အသုံးပြုနိုင်မည်ဖြစ်ပါသည်။

အမာရွတ်ဖြစ်နေသော ကြိမ်အတွက် ဈေးပေါသော အခြင်းပေး ဗာနစ်ကို ဘယ်မှာဝယ်နိုင်ပါသလဲ

အီမယ်ဝိုင်ယာထုတ်လုပ်ရေးအတွက် ပညာရှင်အဆင့် အခြေကျစေသော ပိတ်ဆို့မှု ကော်တင်းတစ်မျိုးအဖြစ် Kuaike Precision Alloy သည် သင့်အတွက် ရွေးချယ်နိုင်ရန် အရည်အသွေးမြင့်မားပြီး စရိတ်သက်သာသော အခြေကျစေသည့် ပစ္စည်းများကို ပေးဆောင်နိုင်ပါသည်။ စက်မှုလုပ်ငန်းတွင် ဦးဆောင်နေသော ဝိုင်ယာအခြေကျစေသည့် ကော်တင်းများ ထုတ်လုပ်သည့် ကုမ္ပဏီတစ်ခုအဖြစ် Kuaike Precision Alloy သည် အဆင့်မြင့်အရည်အသွေးရှိသော အင်္ဂါသား ကော်တင်းများကို ပေးဆောင်ပြီး ဝိုင်ယာထုတ်လုပ်ခြင်း၏ တင်းကျပ်သော စံနှုန်းများကို ဖြည့်ဆည်းပေးပါသည်။ စွမ်းအင်လုပ်ငန်း၊ ယေဘုယျ စက်မှုလုပ်ငန်း အသုံးပြုမှု သို့မဟုတ် အသုံးပြုမှု၏ သီးခြားရည်ရွယ်ချက်များအတွက် အခြေကျစေသည့် ကော်တင်းကို သင်လိုအပ်ပါက Kuaike Precision တွင် အတွေ့အကြုံရှိပြီး ပံ့ပိုးမှုအရင်းအမြစ်များရှိကာ ကုန်ကျစရိတ် ချွေတာနိုင်မည့် အခွင့်အလမ်းများကို ပေးဆောင်နိုင်ပါသည်။ ၎င်းတို့၏ အခြေကျစေသည့် ကော်တင်း ဖြေရှင်းနည်းများနှင့် ဝိုင်ယာထုတ်လုပ်မှု၏ အရည်အသွေးကို မြှင့်တင်ရန် နောက်ထပ် အချက်အလက်များကို ရယူရန် Kuaike Precision Alloy သို့ ဆက်သွယ်ပါ။

အကြောင်းအရာများ

- အလွှာကာပေးထားသော ထုတ်ကုန်များ၏ အမျိုးအစားများကို လက်ကားရောင်းချရန် ရရှိနိုင်ပါသည်။

- အီမယ်ဝိုင်ယာအတွက် အဆင့်မြင့် အခြေကာကွယ်ရေး ပေါင်းစပ်ပစ္စည်း

- အိုင်ဆူလေးရှင်းဓာတ်ပါသော ဆေးသည် ဆေးကြိုး၏ စွမ်းဆောင်ရည်ကို မည်သို့သက်ရောက်မှုရှိပါသနည်း။

- ကြိုးပြုလုပ်ရာတွင် သင့်တော်သော ခြုံထားသည့်အလွှာကို မည်သို့ရွေးချယ်မည်နည်း။

- အမာရွတ်ဖြစ်နေသော ကြိမ်အတွက် ဈေးပေါသော အခြင်းပေး ဗာနစ်ကို ဘယ်မှာဝယ်နိုင်ပါသလဲ

EN

EN

AR

AR

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

IW

IW

ID

ID

SR

SR

SL

SL

UK

UK

VI

VI

HU

HU

MT

MT

TH

TH

TR

TR

AF

AF

MS

MS

GA

GA

AZ

AZ

MN

MN

MY

MY

KK

KK

UZ

UZ

KY

KY

BN

BN