Ang proseso ng produksyon ng seramiko ay medyo kumplikado, nangangailangan ng pagbibigay-pansin sa detalye upang makagawa ng mas mahusay na produkto. Napakalinaw ng punto na ito para sa amin, ang Kuaike Precision Alloy, bilang isang tagagawa ng seramiko: kailangan naming mahigpit na kontrolin ang mga depektong ito upang maibigay sa aming mga customer ang pinakamahusay na produkto. Sa pamamagitan ng paggamit ng mga pamamaraan ng QC, nababawasan ang mga depekto at maaari nating likhain Mga seramik na may pinakamahusay na kalidad.

Mga Benepisyo ng Kontrol sa Depekto sa Paggawa ng Seramiko

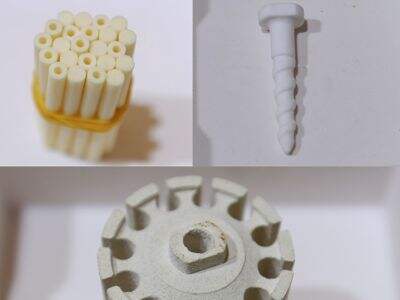

Ang produksyon ng ceramic na walang depekto ay nagdudulot ng maraming benepisyo sa parehong tagagawa at mamimili. Isa sa pangunahing bentahe nito ay ang kalidad ng produkto at ang pagkakaroon ng maaasahang paraan upang mapanatili ito nang buong consistent. Sa pamamagitan ng maagang pagtuklas at pagwawasto sa mga depekto sa proseso ng pagmamanupaktura, masiguro natin na bawat bahagi ng sasakyan na gawa sa ceramic tulad ng ceramic sheath thermocouple ay sumusunod sa mataas na pamantayan ng kalidad. Ang ganitong konsistensya ay hindi lamang nagpapalakas sa ating imahe bilang isang mapagkakatiwalaang tagagawa, kundi nagbibigay din ng tiwala sa mga kliyente na magreresulta sa mas mataas na kasiyahan at katapatan.

Sa kontrol sa mga depekto, isa pang benepisyo ay ang pagbaba sa basura at sa mga produkto na nangangailangan ng pagsasaayos. Mayroon ding sayang sa badyet dahil ang ceramic na may mababang kalidad ay nakakaapekto sa ating kita. Sa pamamagitan ng mahigpit na protokol sa kontrol ng kalidad, ang mga prosesong ito ay maaaring mapabilis upang mabawasan ang produksyon ng depektibong produkto at ang pangangailangan sa pagsasaayos, makatipid sa gastos sa produksyon, at makamit ang mas responsable na operasyon sa pagmamanupaktura na kaaya-aya sa kalikasan.

Proseso ng kontrol sa kalidad para sa pagmamanupaktura ng ceramic

Bukod sa SPC, kami ang nagsasagawa ng buong pagsusuri at kontrol. Ayon sa mga kahilingan ng mga kliyente. Ang mga inspeksyon na ito ay nakatutulong sa amin upang madiskubre ang mga depekto sa mas maagang yugto at magawa ang kinakailangang pagwawasto bago pa ganap na maisaayos ang mga produkto. Sa pamamagitan ng biswal na inspeksyon, pagsukat ng dimensyon, at pagsusuri sa materyal, mailalabas namin ang bawat produktong keramiko tulad ng ceramic thermocouple protection tubes gawa sa mataas na kalidad.

Sa konklusyon, sa pamamagitan ng epektibong mga paraan ng kontrol sa kalidad at masusing pagmomonitor sa produksyon, magagawa naming mapigilan ang mga depekto habang ginagawa ang mga keramika upang makagawa ng mahuhusay na huling produkto para sa aming mga kliyente dito sa Kuaike Precision Alloy. Ang aming dedikasyon sa mataas na kalidad at masusing pagbabantay sa eksaktong sukat ay nagtulak sa amin upang maging nangungunang tagagawa sa larangang ito, tinitiyak na ang aming mga keramika ay nakatuon sa kahusayan.

Paggawa ng Kalidad ng mga Produkto sa Industriya ng Keramika

Kapagdating sa pagmamanupaktura ng mga keramika, napakahalaga para sa amin ang pagbibigay-pansin sa detalye. Isa sa mga paraan upang kontrolin ang mga depekto ay ang paggamit lamang ng mga hilaw na materyales na may mataas na kalidad. Kapag ginamit ang mga de-kalidad na hilaw na materyales, tulad ng luwad at iba pang pandagdag, mas mapapaliit ang posibilidad ng pagkabuo ng mga depekto. Kailangan din ang isang mataas na antas ng kasanayan at kompetenteng lakas-paggawa na kayang magproseso ng produksyon nang may husay at pag-iingat. Ang regular na pagpapanatili at pag-aayos ng mga makina ay nakatutulong din upang masiguro ang kalidad ng produkto dahil ang hindi maayos na gumagana mga makina ay maaaring magdulot ng mga hindi pare-pareho sa huling produkto.

Mga Karaniwang Isyu na Nakikita sa Mga Produkto ng Keramika sa Bilihan

Kahit na may mga pinakamahusay na kasanayan sa lugar, ang mga abnormalidad ay maaaring makilala sa ceramic production. Ang ilan sa mga madalas na depekto sa pakyawan na mga produktong ceramic ay ang mga pinhole, warping at crack. Ang mga pinholes ay maliliit na butas na maaaring mangyari sa nakikitang bahagi ng iyong ceramic na piraso, kadalasan dahil sa mga air pocket na nakulong sa clay o glaze. Ang dishing ay resulta ng pagiging maluwag ng center piece sa panahon ng pagpapaputok, kung saan nagiging mas malaki ang mga ito ay bumubukas sa gitna. Dahil sa pantay o hindi pantay na pagpapatayo at paglamig ng ceramic crack ay maaaring mangyari. Sa maagang pagkilala sa laganap na mga bahid na ito, posible para sa mga manufacturer na magsagawa ng pagwawasto para maiwasan ang mga ito sa mga susunod na pagtakbo.

EN

EN

AR

AR

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

IW

IW

ID

ID

SR

SR

SL

SL

UK

UK

VI

VI

HU

HU

MT

MT

TH

TH

TR

TR

AF

AF

MS

MS

GA

GA

AZ

AZ

MN

MN

MY

MY

KK

KK

UZ

UZ

KY

KY

BN

BN