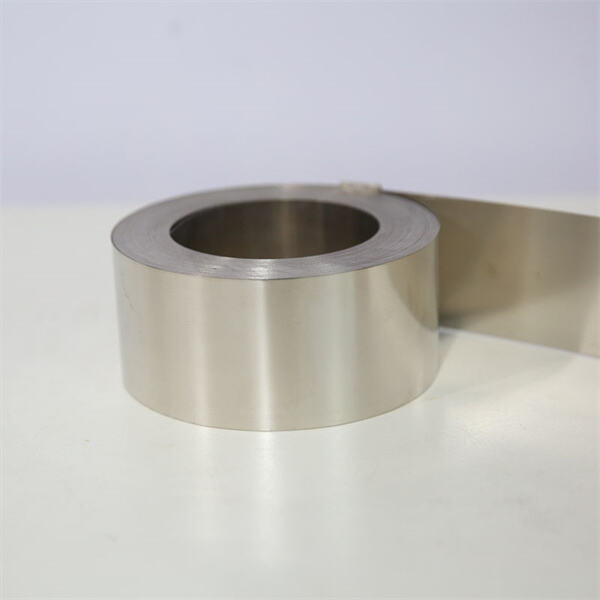

We study a specific material, chromium and nickel alloy, which is widely used in many products. It is composed of two key elements, including ceramic thermocouple tube chromium and nickel. All of these components act toward the end of strengthening and toughening things, which is why it's such a sought-after quality. But in this article, we will find how chromium and nickel alloy works and how it is significant for many jobs in various industries

It is known for its high strength, corrosion, and oxidation resistance, which is characteristic of chromium and nickel alloys. So it can take a fair amount of strain and stress before snapping. This alloy is resistant to damage, so it is frequently adopted in the production of tools, machines, and even jewelry. This alloy has special properties, thanks to the blend of chromium and nickel. For instance, consider a tool you use daily. A tool made from chromium and nickel alloy will outperform and outlast a tool made from weaker materials.

Chromium and nickel are key elements in the production of this particular alloy. Every single material has its own contribution to the alloy, providing the important properties. Chromium helps the alloy resist rust and corrosion. Rust is when metal alloy of chromium and nickel is damaged by water or air over a period of time. This can lead to materials degradation and malfunction. But I mean, nickel does make the alloy stronger and more durable so it can stand up to harsh environments. Combining these two in the proper proportions creates a beautiful material that is used for a wide variety of things, from kitchen tools to automotive components.

These are some ways up you can understand exactly what works in what pattern: It is very much important that a perfect mixture of these elements is used to get the best results out of the Iron chromium and nickle alloy. Proper mixing of these can lead to the material being structurally more durable and prompt to damage. If a company uses that alloy to make a machine, the machine will run better and last longer if this alloy is made correctly. Wherever we have to use the alloy in the proper form, it may take a long time and work effectively, even in factories and field websites.

A great advantage of chromium and nickel alloy is its versatility, which can be used in all kinds of fields. Another common use is in construction, since strong materials are required to do things like build buildings and bridges. In the automotive arena, it is also present, enabling safe, reliable cars. Moreover, this alloy can be found in household products like kitchen utensils and gadgets. That is a good representation of the versatility of the material and how it can tailor itself to suit varying needs across different sectors.

Corrosion resistanceAnother most important properties of chromium and nickel alloy is its ability to resist corrosion. Corrosion is a breakdown of a material in response to contact with water or chemicals. This indicates that the fabric cannot easily penetrate dust and moisture. For instance, when employing this alloy in pipes or machinery, it assists in their prolonged life and enhances their operating efficiency, which is extremely essential in multiple sectors. We can make all of this stay dry and running smooth by using chromium and nickel alloy in some areas where it will come into contact with water or caustic chemicals.

Provide a professional technical support team to help users solve technical problems, conduct innovative designs, and produce diversified and personalized products to ensure that user needs are met. We plan to combine precision alloys with other materials to improve the comprehensive performance of materials, and reduce energy consumption and pollution in the production process by optimizing alloy composition and preparation process.

Kuaike ensures that all kinds of user needs are guaranteed while improving efficiency and quality. We will also visit users regularly to understand their satisfaction and changes in needs, optimize service processes through data analysis, and reduce users' maintenance and time costs to improve cost performance. Transparent service process allows users to understand the service progress in real time through the online platform, improving user experience.

The precision alloy products provided by Kuaike can maintain stable performance under various conditions, and its excellent quality can reduce the cost of frequent replacement by users. Our precision alloy products have special magnetic properties, electrical properties or thermal expansion coefficients, which are suitable for high-precision and high-sensitivity applications, and can also be optimized by precisely controlling the preparation process to meet specific application requirements.

Kuaike's precision alloy products have been sold all over the world and have important applications in electronics, automobiles, medical care, energy and other fields. The production and sales center of Kuaike covers an area of 5,000 square meters and has more than 30 types of precision alloys that meet customer needs. In terms of industrial chain integration, the company maintains close cooperation with downstream end users to optimize the cost structure and enhance overall competitiveness.

Copyright © Kuaike Precision Alloy (Shanghai) Co., Ltd. All Rights Reserved