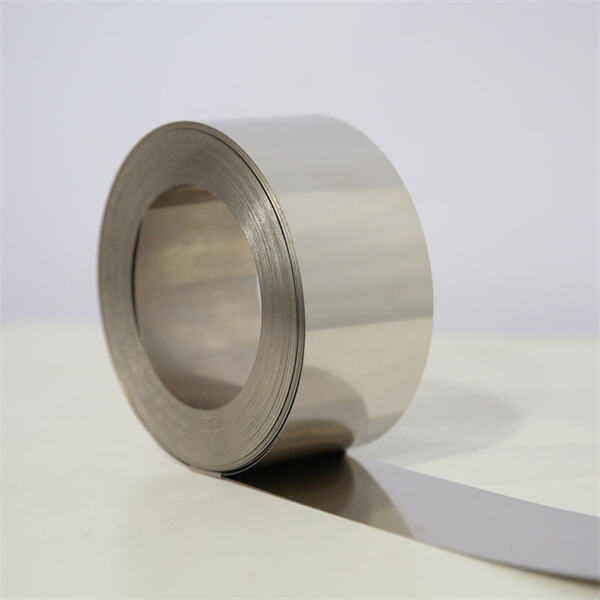

Two metals you can combine together and create an alloy is chromium and nickel. When two or more metals are mixed together, they form an alloy. Chromium and nickel is mixed to form a robust and useful alloy, which is called the chrome-nickel alloy. It specifies a unique material that has many applications in different industries.

It is commonly known that copper-nickel alloy is a useful material used in a variety of applications and industries, identical to Kuaike Precision Alloy's product nickel chromium alloy. It is strong meaning that it will not fall apart under pressure. This material also has a long lifespan so does not need to be replaced often. Also, chrome-nickel alloy contains copper and silicone, which makes it rust-resistant, meaning it will not be easily damaged by water or anything that causes rust. These excellent properties allow chrome-nickel alloy to be used in environments that were unsuitable for more traditional materials.

Alloy with chrome and nickel containing other elements such as iron and carbon is called chrome-nickel alloy, as well as the nickel chrome wire made by Kuaike Precision Alloy. These additional ingredients also serve to further strengthen the alloy. When these metals are combined, they form a very durable material. That means can it be used in things like machines, tools, and anything else that needs to be durable. Chrome-nickel alloy has the added benefit of being able to withstand extreme heat. That means it doesn’t easily melt or lose shape, which makes it ideal to use in places where things can get extremely hot.

And, one of the greatest benefits chrome-nickel alloy can provide is its incredible strength, along with Kuaike Precision Alloy's product ceramic thermocouple tube. Its durability helps make it great for jobs where materials need to last a long time and bear a lot of wear and tear. It is used, for example, on assembly lines, in factories where things are manufactured, on construction sites where buildings are constructed, and in cars where they are built. A very relevant reason to go with chrome-nickel alloy, is its resistance to rust. It is this property that allows it to be used safely in environments where it might become wet or exposed to harsh conditions without getting damaged.

They seem to be a chrome-nickel alloy that engineers love to plan because they are hard and stable, also the Corrosion-resistant alloys made by Kuaike Precision Alloy. This alloy allows them to construct all sorts of things, including bridges that cars drive over, skyscrapers that people work and live in, and in some cases lots of spacecraft to go into outer space. Chrome-nickel alloy's ability to withstand high-temperature environments and resist rust make it a popular material for engineering projects. Engineering metal making a new skyscraper that needs to be tall and strong, or moving a new type of airplane that can fly at adjustable speeds, Chrome-nickel alloy is one of the common and necessary metals in their work.

Well, maybe, the most important characteristics of chrome-nickel alloy is strength and durability, identical to Kuaike Precision Alloy's product Nickel-chromium. It can withstand extensive wear and does not break or bend easily making it the perfect choice for creating tools and machinery. These arrows have to be super tough and durable for multiple uses without being damaged. Chrome-nickel alloy also resists rust, so it is suitable for use in areas that make other materials weak and deteriorate. As a result, chrome-nickel alloy is one of the most invaluable materials utilized in a wide range of applications and industries.

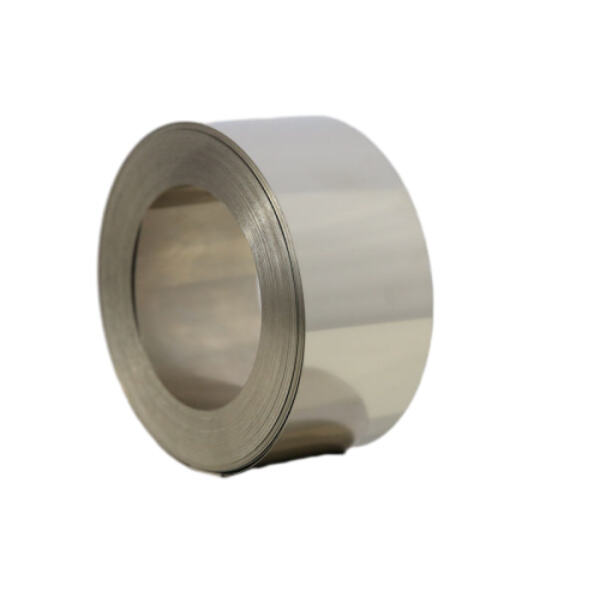

Provide a professional technical support team to help users solve technical problems, conduct innovative designs, and produce diversified and personalized products to ensure that user needs are met. We plan to combine precision alloys with other materials to improve the comprehensive performance of materials, and reduce energy consumption and pollution in the production process by optimizing alloy composition and preparation process.

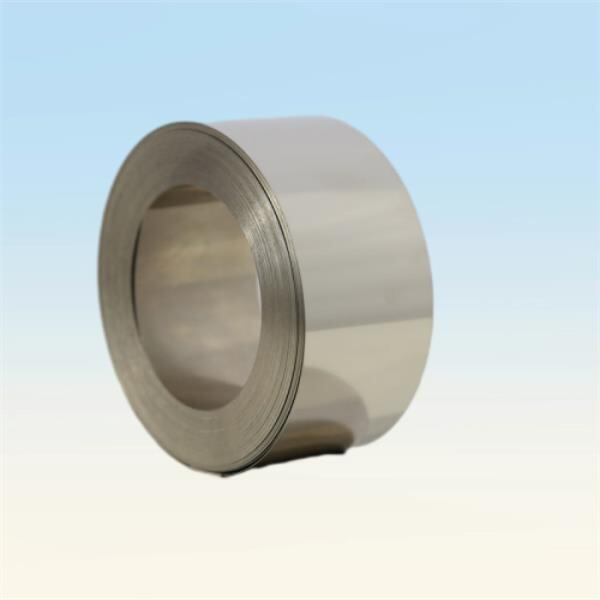

The precision alloy products provided by Kuaike can maintain stable performance under various conditions, and its excellent quality can reduce the cost of frequent replacement by users. Our precision alloy products have special magnetic properties, electrical properties or thermal expansion coefficients, which are suitable for high-precision and high-sensitivity applications, and can also be optimized by precisely controlling the preparation process to meet specific application requirements.

Kuaike's precision alloy products have been sold all over the world and have important applications in electronics, automobiles, medical care, energy and other fields. The production and sales center of Kuaike covers an area of 5,000 square meters and has more than 30 types of precision alloys that meet customer needs. In terms of industrial chain integration, the company maintains close cooperation with downstream end users to optimize the cost structure and enhance overall competitiveness.

Kuaike ensures that all kinds of user needs are guaranteed while improving efficiency and quality. We will also visit users regularly to understand their satisfaction and changes in needs, optimize service processes through data analysis, and reduce users' maintenance and time costs to improve cost performance. Transparent service process allows users to understand the service progress in real time through the online platform, improving user experience.

Copyright © Kuaike Precision Alloy (Shanghai) Co., Ltd. All Rights Reserved