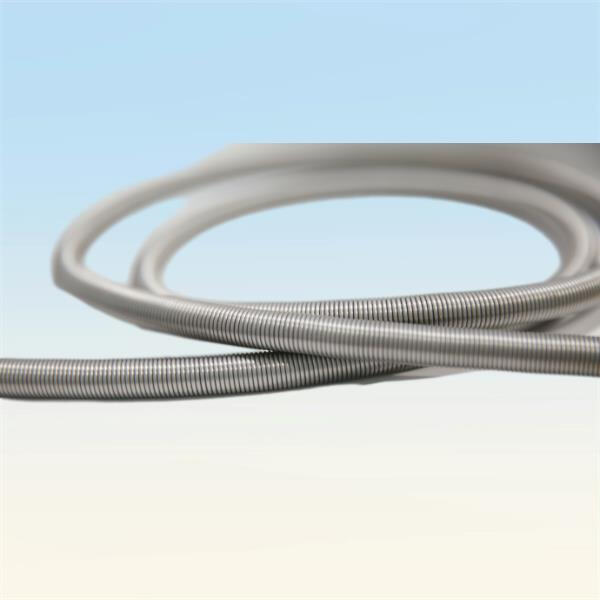

Nichrome wire is a unique type of wire used for heating for many industries. Nickel and chromium are the two metals that it is made from. They are combined to form a wire that can maintain its strength and perform well at high temperatures. This wire is very significant for heating because it has brute handle extremities without getting damages. Isn’t it incredible to know the importance of nickel chromium wire in heating different things in several industries

Nickel chromium wire is a popular choice for many industries because it is highly resistant to high operating temperatures and as such my fracture or degradation. This is a key feature, as industries often need to heat things in order to make products. For instance, they could be inflating metals, glass or even food. Nickel chromium wire continues to perform effectively, even with frequent use. One thing is durability which is crucial for the industries and helps them run their production lines effectively without regular maintenance.

Nickel chromium wire is the superhero of the heating world. Because it has so many fantastic skills! One of its most desirable features is that it heats up quickly and evenly. That's very important in industries where you previously needed energy to heat things quickly and make sure they were heated all the way through. For example, if a company is manufacturing metal parts, these must be evenly heated in order for them to be molded properly. Because, in the case of uneven heating, it causes defects in the products

Nickel chromium wire is revolutionizing the industrial sector's use of electrical resistance heating due to its capacity to heat objects quickly and evenly. That is to say, businesses can create their products more quickly and more effectively. Faster production allows them to better meet customer demands and in turn higher profits. It’s good for business, and it also helps the people who use the products because they can get what they are looking for more quickly.

This is because the construction of these types of nichrome wire is uninhabited as compared to other types, such as those built to only withstand temperatures up to around 500 degrees Celsius. So, it is essential to use the right kind of wire nickel chromium wire so that it serves the purpose that the industry requires. Using the wrong type could lead to overheating or damage, and that would be expensive.

It’s also important to maintain the systems properly. That means periodically inspecting the wire to be sure it is not kinked or broken in some way. Any failures that occur must be addressed promptly in order for the heating system to continue to function effectively. Proper care for nickel chromium wire is essential to ensure chromium and nickel wire is capable of providing industries to continue being able to produce their products quickly and with the highest quality possible. Routine inspections can prevent small problems from becoming out of hand.

Then think about how fast the wire has to get things hot. In the case that it is required to heat things very fast, its importance to select the type of wire its heating fast is highly crucial. Finally, consider how much frequent use the wire will get and how long a life span it needs to have. Industries desire to choose appropriate nickel chromium wire for their heating application. This makes sure that the wire we produce is up to the job and gives industries the best chance at producing their products as quickly as possible.

Provide a professional technical support team to help users solve technical problems, conduct innovative designs, and produce diversified and personalized products to ensure that user needs are met. We plan to combine precision alloys with other materials to improve the comprehensive performance of materials, and reduce energy consumption and pollution in the production process by optimizing alloy composition and preparation process.

Kuaike ensures that all kinds of user needs are guaranteed while improving efficiency and quality. We will also visit users regularly to understand their satisfaction and changes in needs, optimize service processes through data analysis, and reduce users' maintenance and time costs to improve cost performance. Transparent service process allows users to understand the service progress in real time through the online platform, improving user experience.

Kuaike's precision alloy products have been sold all over the world and have important applications in electronics, automobiles, medical care, energy and other fields. The production and sales center of Kuaike covers an area of 5,000 square meters and has more than 30 types of precision alloys that meet customer needs. In terms of industrial chain integration, the company maintains close cooperation with downstream end users to optimize the cost structure and enhance overall competitiveness.

The precision alloy products provided by Kuaike can maintain stable performance under various conditions, and its excellent quality can reduce the cost of frequent replacement by users. Our precision alloy products have special magnetic properties, electrical properties or thermal expansion coefficients, which are suitable for high-precision and high-sensitivity applications, and can also be optimized by precisely controlling the preparation process to meet specific application requirements.

Copyright © Kuaike Precision Alloy (Shanghai) Co., Ltd. All Rights Reserved