And nickel chromium is a unique type of metal that has some really neat properties. It is a mixture of two metals, wire nickel and chromium. These metals are located on the periodic table which is the chart that displays how all the elements create everything around us. Nickel and chromium combine to form a hard and strong alloy. This kind of unique metal can be used for various things in our normal life

Nickel chromium in factories and industries alloy of chromium and nickel is used in many different manners in factories and industries. Its generation is commonly used to produce heating elements for stoves and ovens. These parts of the stove are what we use to heat our food -- they get really hot. It is one of the added elements in the making of certain metal alloys, which are a configuration of certain metals that forms a unique combination of properties.

Nickel chromium with rust resistant properties are ideal in locations that heat up really hot That means it can be used in places where other substances would quickly wear, or break apart, including industrial furnaces used to melt metals and factories that handle chemicals.

And its history is long and not very simple. Over the years, scientists and engineers have struggled to find just the right recipe of chromium and nickel alloy, mixed with other elements, to make it strong, durable, rust-resistant. Indeed, this work has been ongoing and it has resulted in the creation of some highly sophisticated materials that are being used today in various industries.

Nickel chromium is a fascinating and versatile material with a variety of applications across many industries. From strength and toughness to rust and high-heat resistance, it is no wonder why it is often used in countless fields.

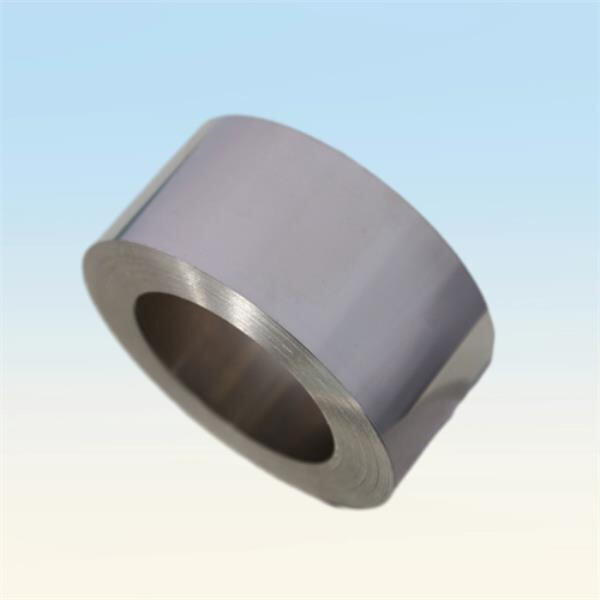

The precision alloy products provided by Kuaike can maintain stable performance under various conditions, and its excellent quality can reduce the cost of frequent replacement by users. Our precision alloy products have special magnetic properties, electrical properties or thermal expansion coefficients, which are suitable for high-precision and high-sensitivity applications, and can also be optimized by precisely controlling the preparation process to meet specific application requirements.

Kuaike's precision alloy products have been sold all over the world and have important applications in electronics, automobiles, medical care, energy and other fields. The production and sales center of Kuaike covers an area of 5,000 square meters and has more than 30 types of precision alloys that meet customer needs. In terms of industrial chain integration, the company maintains close cooperation with downstream end users to optimize the cost structure and enhance overall competitiveness.

Provide a professional technical support team to help users solve technical problems, conduct innovative designs, and produce diversified and personalized products to ensure that user needs are met. We plan to combine precision alloys with other materials to improve the comprehensive performance of materials, and reduce energy consumption and pollution in the production process by optimizing alloy composition and preparation process.

Kuaike ensures that all kinds of user needs are guaranteed while improving efficiency and quality. We will also visit users regularly to understand their satisfaction and changes in needs, optimize service processes through data analysis, and reduce users' maintenance and time costs to improve cost performance. Transparent service process allows users to understand the service progress in real time through the online platform, improving user experience.

Copyright © Kuaike Precision Alloy (Shanghai) Co., Ltd. All Rights Reserved