- ওভারভিউ

- সংশ্লিষ্ট পণ্য

| উৎপত্তির স্থান: | চীনা |

| ব্র্যান্ডের নাম: | কোয়ার্ক |

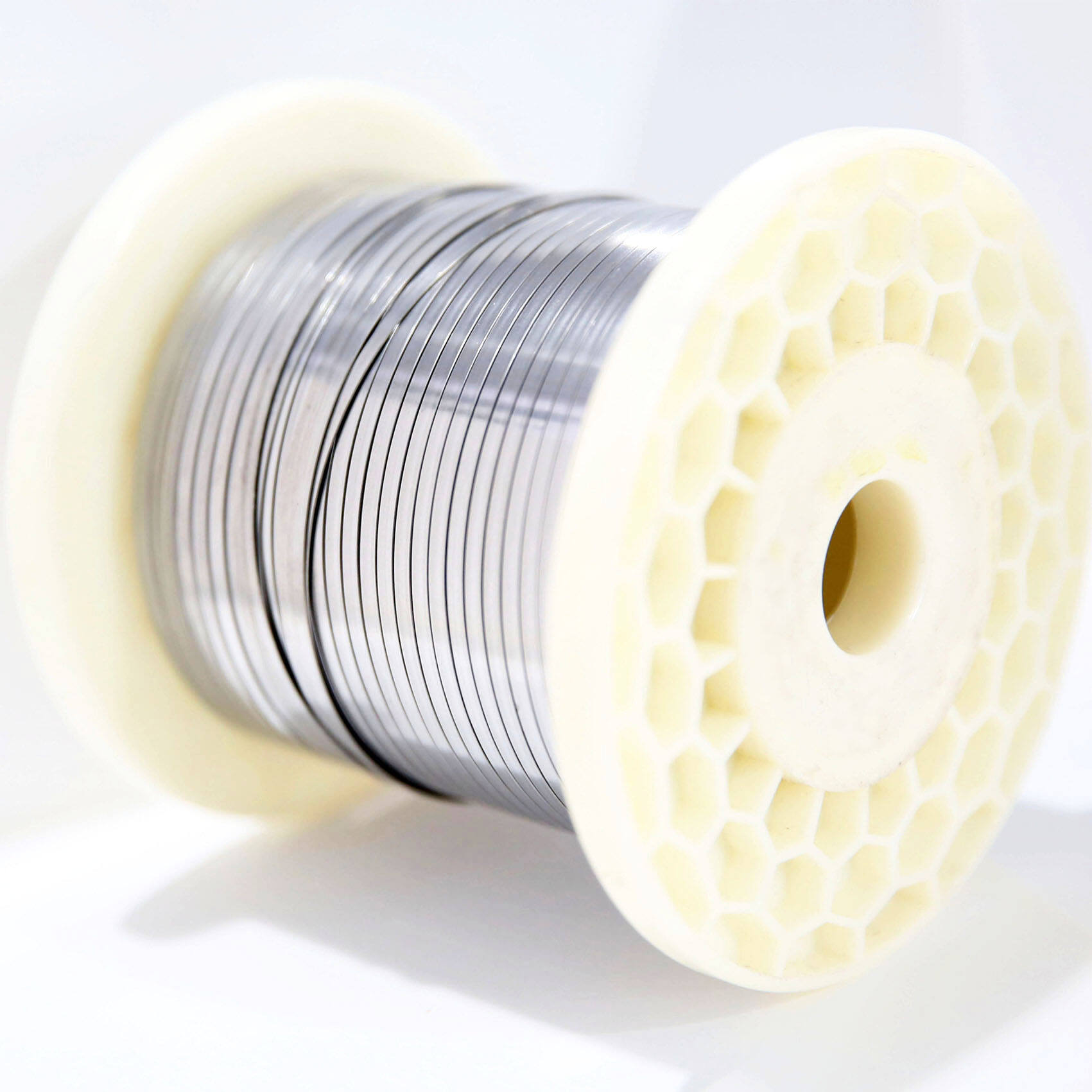

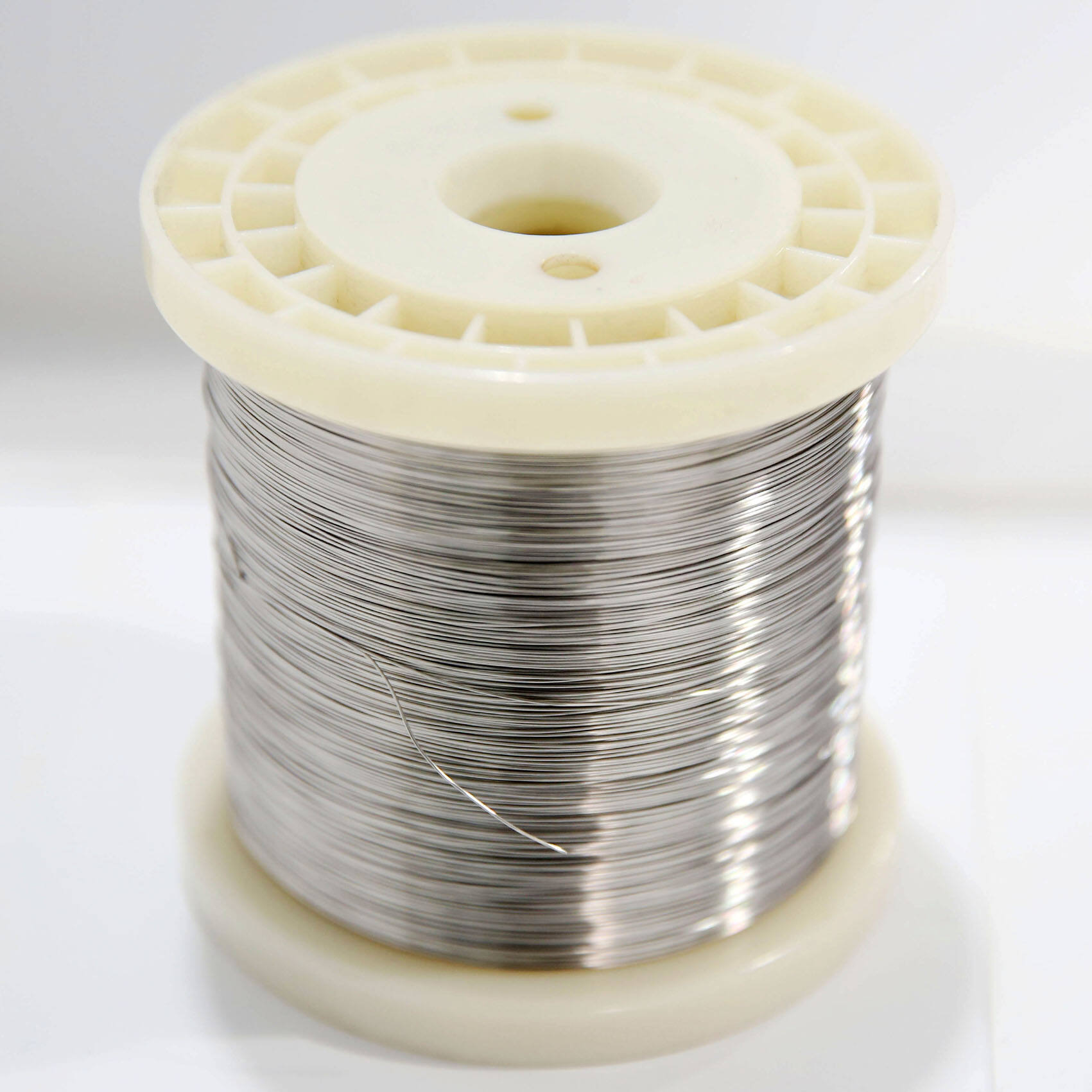

| মডেল নম্বর: | নিকেল ক্রোম তার |

| সংগঠন: |

| ন্যূনতম অর্ডার পরিমাণ: | 0.5মিমি 1কেজি |

| মূল্য: | 24$ |

| প্যাকিং বিবরণ: | শক্ত কাগজ |

| ডেলিভারি সময়: | দুই দিন |

| পেমেন্ট শর্ত: | ডেলিভারির আগে অর্থ প্রদান |

| সরবরাহ ক্ষমতা: | 10T |

বৈশিষ্ট্য:

নাইক্রোম তার উচ্চ বৈদ্যুতিক প্রতিরোধ ক্ষমতা, চমৎকার উচ্চ-তাপমাত্রা সহনশীলতা এবং উচ্চতর জারণ প্রতিরোধ ক্ষমতা প্রদর্শন করে, যা এটিকে বৈদ্যুতিক গরম করার উপাদান এবং শিল্প গরম করার অ্যাপ্লিকেশনের জন্য আদর্শ করে তোলে।

রচনাঃ

- নিকেল (Ni): 80% থেকে 20%

- ক্রোমিয়াম (Cr): 20% থেকে 80%

- পারফরম্যান্স অপ্টিমাইজেশনের জন্য সামান্য মৌলিক পদার্থ (Fe, Al ইত্যাদি সহ)

স্ট্যান্ডার্ড খাদ:

- Ni80Cr20 (80% Ni + 20% Cr, সবচেয়ে সাধারণ)

- Ni60Cr15, Ni70Cr30, Ni90Cr10

- Ni35Cr20, Ni20Cr25

প্রধান বৈশিষ্ট্য:

• উচ্চ রোধকতা (1.0-1.5 μΩ·m) - হিটিং এলিমেন্টের জন্য অপটিমাল

• তাপীয় স্থিতিশীলতা (কার্যকরী পরিসর: 1000-1400°C)

• স্ব-প্যাসিভেটিং জারণ স্তর (Cr2O3 গঠন)

• উচ্চ তাপমাত্রায় চমৎকার যান্ত্রিক শক্তি

• নিরবিচ্ছিন্ন উচ্চ তাপমাত্রা পরিচালনায় দীর্ঘ সেবা জীবন

অপারেশনাল গাইডলাইন:

! আগেভাগে ব্যর্থতা প্রতিরোধের জন্য তাপমাত্রা সীমা মেনে চলা আবশ্যিক

! বাঁকানো বা টান থেকে যান্ত্রিক চাপ এড়ান

! সুরক্ষামূলক অক্সাইড স্তর রক্ষার জন্য শুষ্ক সংরক্ষণ অবস্থা বজায় রাখুন

| এলোই গ্রেড | ব্যাসার্ধ ((মিমি) | রোধকতা μΩ·m(20℃) |

| Cr20Ni80 | <0.50 | ১.০৯±০.০৫ |

| 0.50~3.00 | 1.13±0.05 | |

| >3.00 | 1.14±0.05 | |

| Cr30Ni70 | <0.50 | ১.১৮±০.০৫ |

| ≥০.৫০ | 1.20±0.05 | |

| Cr15Ni60 | <0.50 | ১.১২±০.০৫ |

| ≥০.৫০ | 1.15±0.05 | |

| Cr20Ni35 | Cr20Ni30 <0.50 | ১.০৪±০.০৫ |

| ≥০.৫০ | 1.06±0.05 |

অ্যাপ্লিকেশন:

▸ বৈদ্যুতিক তাপীয় সিস্টেম: চুল্লি, তাপন টিউব, চুলা, সোল্ডারিং লোহা, শুষ্ককারী যন্ত্র

▸ শিল্প তাপ: গলন চুল্লি, তাপ চিকিত্সা সিস্টেম, কাচ প্রক্রিয়াকরণ

▸ ল্যাবরেটরি সরঞ্জাম: উচ্চ-তাপমাত্রা পরীক্ষা, রোধাঙ্ক তাপন উপাদান

▸ ইলেকট্রনিক্স: রোধাঙ্ক তার, ফিউজ, ভেপিং অ্যাটমাইজার কয়েলস

▸ সংযোজনীয় উত্পাদন: FDM প্রিন্টার উত্তপ্ত বিছানার উপাদান

স্পেসিফিকেশন:

| ব্যাস | কেন্দ্রীয় রোধ | রোধের পরিসর | ব্যাস | কেন্দ্রীয় রোধ | রোধের পরিসর |

| 0.030 | 1542 | 1388-1696 | 0.040 | 867.4 | 780.7-954.1 |

| 0.050 | 555.1 | ৪৯৯.৬-৬১০.৬ | 0.060 | 385.5 | ৩৪৭-৪২৪.১ |

| 0.070 | 283.2 | ২৬০.৫-৩০৫.৯ | 0.080 | 216.8 | ১৯৯.৫-২৩৪.১ |

| 0.090 | 171.3 | ১৫৭.৬-১৮৫ | 0.100 | 138.8 | ১২৭.৭-১৪৯.৯ |

| 0.120 | 96.38 | ৮৮.৬৭-১০৪.১ | 0.150 | 61.68 | ৫৭.৩৬-৬৬ |

| 0.200 | 34.7 | ৩২.৬২-৩৬.৭৮ | 0.250 | 22.21 | ২০.৮৮-২৩.৫৪ |

| 0.300 | 15.42 | ১৪.৪৯-১৬.৩৫ | 0.400 | 8.674 | ৮.২৪-৯.১০৮ |

| 0.450 | 6.853 | ৬.৫১-৭.১৯৬ | 0.480 | 6.024 | ৫.৭২৩-৬.৩২৫ |

| 0.500 | 5.551 | ৫.২৭৩-৫.৮২৯ | 0.550 | 4.756 | ৪.৫১৮-৪.৯৯৪ |

| 0.600 | 3.997 | ৩.৭৯৭-৪.১৯৭ | 0.800 | 2.248 | ২.১৩৬-২.৩৬ |

| 0.900 | 1.776 | ১.৬৮৭-১.৮৬৫ | 1.000 | 1.439 | ১.৩৬৭-১.৫১১ |

প্রতিযোগিতামূলক সুবিধা:

উচ্চ মানের, প্রতিযোগিতামূলক মূল্য এবং শক্তিশালী উৎপাদন ক্ষমতা

EN

EN

AR

AR

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

IW

IW

ID

ID

SR

SR

SL

SL

UK

UK

VI

VI

HU

HU

MT

MT

TH

TH

TR

TR

AF

AF

MS

MS

GA

GA

AZ

AZ

MN

MN

MY

MY

KK

KK

UZ

UZ

KY

KY

BN

BN