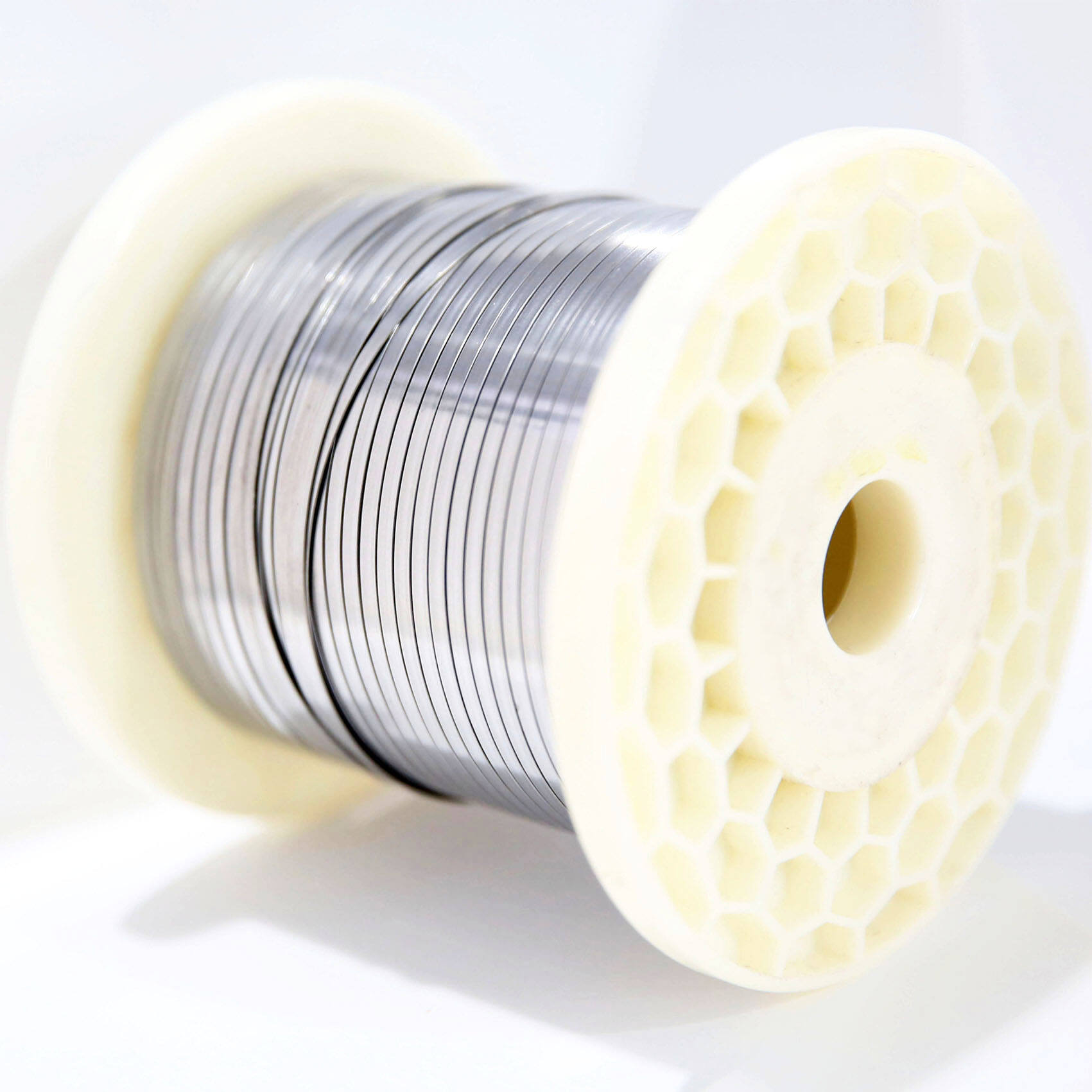

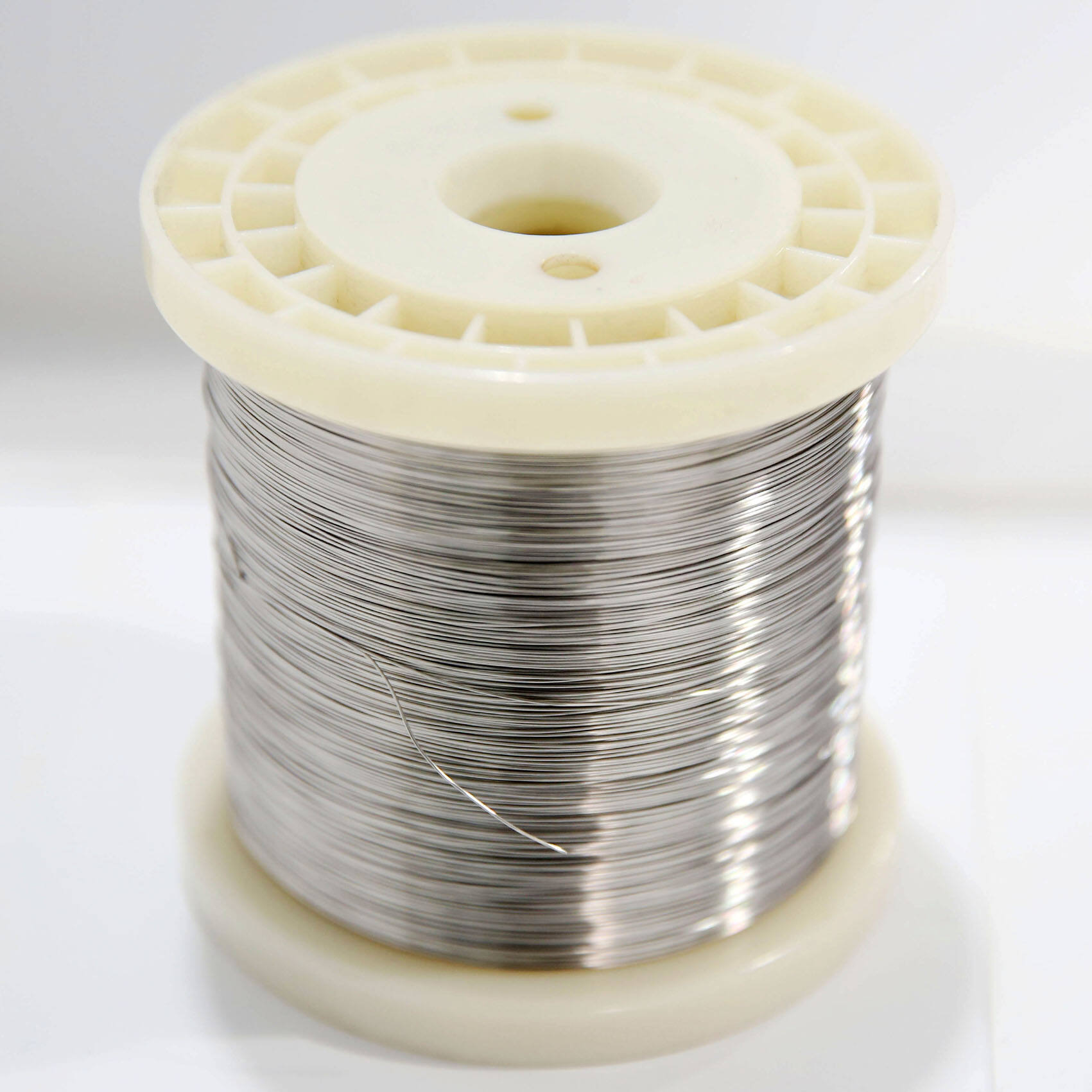

- Overview

- Related Products

| Place of Origin: | Chinese |

| Brand Name: | Quark |

| Model Number: | nickel chrome wire |

| Certification: |

| Minimum Order Quantity: | 0.5mm 1kg |

| Price: | 24$ |

| Packaging Details: | Carton |

| Delivery Time: | Two days |

| Payment Terms: | Payment before delivery |

| Supply Ability: | 10t |

Characteristics:

Nichrome wire exhibits high electrical resistivity, excellent high-temperature endurance, and superior oxidation resistance, making it ideal for electric heating elements and industrial heating applications.

Composition:

- Nickel (Ni): 80% to 20%

- Chromium (Cr): 20% to 80%

- Trace elements (including Fe, Al, etc.) for performance optimization

Standard Alloys:

- Ni80Cr20 (80% Ni + 20% Cr, most common)

- Ni60Cr15, Ni70Cr30, Ni90Cr10

- Ni35Cr20, Ni20Cr25

Key Properties:

• High resistivity (1.0-1.5 μΩ·m) - optimal for heating elements

• Thermal stability (operating range: 1000-1400°C)

• Self-passivating oxidation layer (Cr2O3 formation)

• Excellent mechanical strength at elevated temperatures

• Extended service life in continuous high-temperature operation

Operational Guidelines:

! Critical temperature limits must be observed to prevent premature failure

! Avoid mechanical stress from excessive bending or tension

! Maintain dry storage conditions to preserve protective oxide layer

| Alloy grade | Diameter(mm) | Resistivity μΩ·m(20℃) |

| Cr20Ni80 | <0.50 | 1.09±0.05 |

| 0.50~3.00 | 1.13±0.05 | |

| >3.00 | 1.14±0.05 | |

| Cr30Ni70 | <0.50 | 1.18±0.05 |

| ≥0.50 | 1.20±0.05 | |

| Cr15Ni60 | <0.50 | 1.12±0.05 |

| ≥0.50 | 1.15±0.05 | |

| Cr20Ni35 | Cr20Ni30 <0.50 | 1.04±0.05 |

| ≥0.50 | 1.06±0.05 |

Applications:

▸ Electric heating systems: Furnaces, heating tubes, ovens, soldering irons, dryers

▸ Industrial heating: Smelting furnaces, heat treatment systems, glass processing

▸ Laboratory equipment: High-temperature testing, resistive heating components

▸ Electronics: Resistance wires, fuses, vaping atomizer coils

▸ Additive manufacturing: FDM printer heated bed elements

Specifications:

| Diameter | Center Resistance | Resistance Range | Diameter | Center Resistance | Resistance Range |

| 0.030 | 1542 | 1388-1696 | 0.040 | 867.4 | 780.7-954.1 |

| 0.050 | 555.1 | 499.6-610.6 | 0.060 | 385.5 | 347-424.1 |

| 0.070 | 283.2 | 260.5-305.9 | 0.080 | 216.8 | 199.5-234.1 |

| 0.090 | 171.3 | 157.6-185 | 0.100 | 138.8 | 127.7-149.9 |

| 0.120 | 96.38 | 88.67-104.1 | 0.150 | 61.68 | 57.36-66 |

| 0.200 | 34.7 | 32.62-36.78 | 0.250 | 22.21 | 20.88-23.54 |

| 0.300 | 15.42 | 14.49-16.35 | 0.400 | 8.674 | 8.24-9.108 |

| 0.450 | 6.853 | 6.51-7.196 | 0.480 | 6.024 | 5.723-6.325 |

| 0.500 | 5.551 | 5.273-5.829 | 0.550 | 4.756 | 4.518-4.994 |

| 0.600 | 3.997 | 3.797-4.197 | 0.800 | 2.248 | 2.136-2.36 |

| 0.900 | 1.776 | 1.687-1.865 | 1.000 | 1.439 | 1.367-1.511 |

Competitive Advantage:

High quality, competitive pricing, and strong production capacity

EN

EN

AR

AR

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

IW

IW

ID

ID

SR

SR

SL

SL

UK

UK

VI

VI

HU

HU

MT

MT

TH

TH

TR

TR

AF

AF

MS

MS

GA

GA

AZ

AZ

MN

MN

MY

MY

KK

KK

UZ

UZ

KY

KY

BN

BN