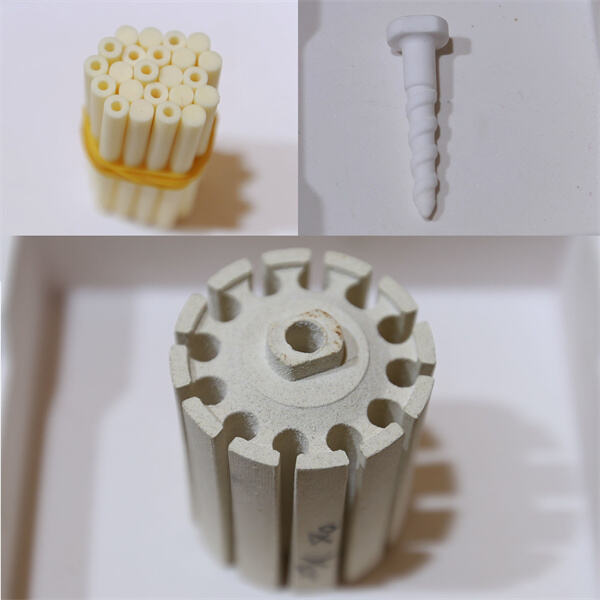

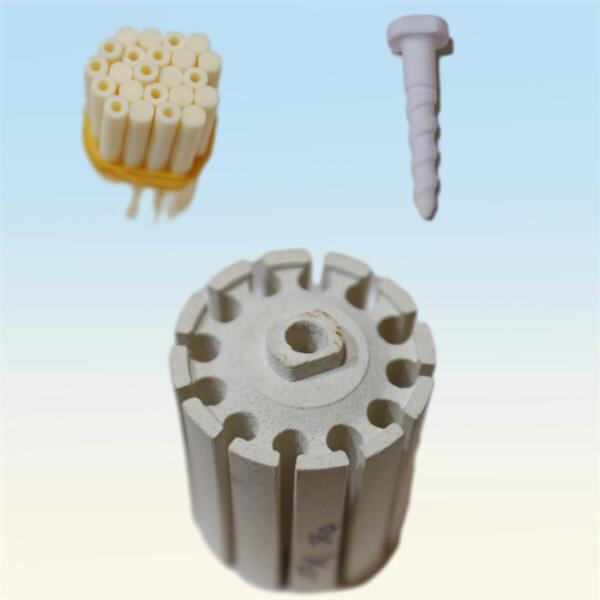

Kuaike Precision Alloy thermocouple materials protection tubes ceramic can keep the thermocouple protected in extremely high-temperature areas. A thermocouple is a device that measures the heat. They detect heat to measure temperature. If the environment is too high in temperature, such as inside an oven or a furnace, thermocouples can be damaged or malfunction. However, with ceramic protection tubes, thermocouples will remain safe and function properly. Let’s find out more information on this protective tube for thermocouples and why they are super useful and necessary in many cases.

In factories or labs that have high temperature, thermocouples require additional protection. This is where the ceramic thermocouple protection tubes steps in! They are fitted with special tubes made from materials called ceramics that are very strong, and can withstand very high temperatures without breaking or melting. This way the thermocouples shall survive the heat and work even in the hottest environments once you put up these ceramic protection tubes. It allows both workers and scientists to get proper temperature readings without needing to worry about damaging or breaking their thermocouples.

Thermocouples are tiny detectives that measure the heat surrounding them and tell us how hot something is. But in extreme heat conditions, thermocouples can easily get hurt or damaged. This is where ceramic protection tubes come in to spoil it. Those tubes essentially function as that protect those heat-sensitive little thermocouples from roasting in the intense flames. Ceramic protection tubes protect thermocouples from damage with the high temperature and allows them to perform their essential function. That means workers and scientists can depend on their thermocouples to provide them the right temperature measurements, every time they need them.

Ceramic thermocouple tube protection tubes are a great aid in accurately measuring temperature. Thus, thermocouples can function correctly and provide an accurate and dependable temperature reading. Thermocouples can be kept safe and functional even in the hottest places with ceramic protection tubes. This is very important because it ensures workers and scientists can know if everything is at the right temperature when baking cookies in an oven, conducting experiments in a lab, and working on important projects inside a factory.

The composite thermocouple sheath have very precise thermal conductivity, which makes them last much longer than other types of thermocouples and allows themselves to perform better.

Well, ceramic thermocouple wire material protection tubes protects thermocouples in hot settings. These tubes help thermocouples last longer and maintain good stability and performance. This is a huge advantage because it entails that workers and scientists don’t have to change their thermocouples as frequently. Thermocouples are costly and take eight to twelve hours for a replacement; therefore, it can save both time and funds by using the ceramic protection tubes. Therefore, if we use ceramic protection tubes provided by Kuaike Precision Alloy to protect the thermocouples, they can measure temperature accurately, and have a long serve life, and don't have to replace them frequently.

Selecting appropriate ceramic protection tube for copper constantan thermocouples is highly dependent on temperature and application environment of the thermocouple. Various ceramic substances are suitable for various temperatures, so you have to select the proper one for you. Considering the range of ceramic protection tubes that Kuaike Precision Alloy offers, you could easily find the best one that perfectly meets your requirements. The careful selection of proper ceramic protection tube for the thermocouple can save you and guarantee the proper function of your thermocouple in challenging high-temperature environments, delivering you accurate results.

Provide a professional technical support team to help users solve technical problems, conduct innovative designs, and produce diversified and personalized products to ensure that user needs are met. We plan to combine precision alloys with other materials to improve the comprehensive performance of materials, and reduce energy consumption and pollution in the production process by optimizing alloy composition and preparation process.

Kuaike ensures that all kinds of user needs are guaranteed while improving efficiency and quality. We will also visit users regularly to understand their satisfaction and changes in needs, optimize service processes through data analysis, and reduce users' maintenance and time costs to improve cost performance. Transparent service process allows users to understand the service progress in real time through the online platform, improving user experience.

The precision alloy products provided by Kuaike can maintain stable performance under various conditions, and its excellent quality can reduce the cost of frequent replacement by users. Our precision alloy products have special magnetic properties, electrical properties or thermal expansion coefficients, which are suitable for high-precision and high-sensitivity applications, and can also be optimized by precisely controlling the preparation process to meet specific application requirements.

Kuaike's precision alloy products have been sold all over the world and have important applications in electronics, automobiles, medical care, energy and other fields. The production and sales center of Kuaike covers an area of 5,000 square meters and has more than 30 types of precision alloys that meet customer needs. In terms of industrial chain integration, the company maintains close cooperation with downstream end users to optimize the cost structure and enhance overall competitiveness.

Copyright © Kuaike Precision Alloy (Shanghai) Co., Ltd. All Rights Reserved