The performance of thermocouples greatly depends on the thermocouple sheath. They protect the thermocouple from damage and make sure it can accurately measure temperatures. When the thermocouple does not have a good sheath, it might not work correctly and will provide us inaccurate temperature readings. This nickel chromium is where thermocouple sheaths come in to play, and this is what you need to know about them

Thermocouples are nice, little temperature sensors that are used at a variety of locations. They are all around us, from ovens to furnaces, even cars! They're made up of two different kinds of metal that produce power when they're heated up. This makes electricity very helpful because it tells us how hot or cold something is. When metals heat, they produce a small electric current, which we can detect. It tells us how hot the object we are observing.

The material itself must be one that can stand up to the temperature of your thermocouple during use. Some materials have better high-temperature resistance, while others are effective at low temperatures. This nickel chrome alloy is why we should pay attention to the environment where the thermocouple can be placed. the material should not react with what it measures. Chemicals will change the temperature readings a lot; therefore we do not get accurate information since the temperature of chemical reactions differs, and we want the opposite!

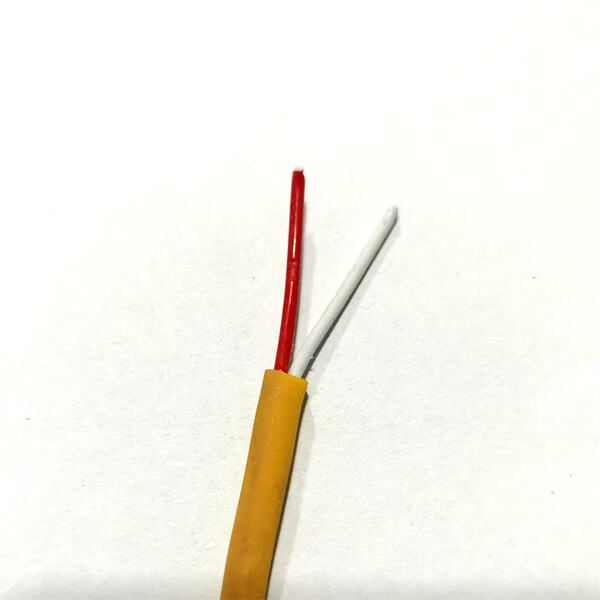

It is very important to use a strong and durable sheath for your thermocouple. This safeguards against dirt, moisture, and chemicals that can be damaging to the thermocouple. A hard sheath protects the wire nickel thermocouple from destructive materials. Additionally, a protective sheath can further reduce the risk of the thermocouple breaking when it is knocked or dropped. Just like if you bump into something and it falls, a good case keeps things safe. The same goes for thermocouples as well!

Thermocouple sheath in high-temperature environments is also very important to protect the thermocouple work, you know? The sheath provides insulation for the sensitive thermocouple wires from a hot environment. It protects the wires from melting or being destroyed by intense heat. Now we can protect the delicate sections of the thermocouple and ensure proper temperature measuring. This thermocouple materials also protects the thermocouple from damage, allowing it to work for a longer time without having to replace it.

A very useful practice is to regularly check your thermocouple sheath for any wear, marks, or signs of damage. Things that we recheck, such as toys or tools to see if they are still in good condition for play or use, should be equally done for thermocouple sheaths. If you see any, dents or changes in color, it’s time to swap out the sheath for a new one. It should use a suitable material for the temperature and environment in which the thermocouple will be used when replacing the sheath. The ceramic thermocouple tube care you give your sheath and when you retire it will dictate how accurate temperature readings you get and also in turn increase the life of your thermocouple.

Provide a professional technical support team to help users solve technical problems, conduct innovative designs, and produce diversified and personalized products to ensure that user needs are met. We plan to combine precision alloys with other materials to improve the comprehensive performance of materials, and reduce energy consumption and pollution in the production process by optimizing alloy composition and preparation process.

The precision alloy products provided by Kuaike can maintain stable performance under various conditions, and its excellent quality can reduce the cost of frequent replacement by users. Our precision alloy products have special magnetic properties, electrical properties or thermal expansion coefficients, which are suitable for high-precision and high-sensitivity applications, and can also be optimized by precisely controlling the preparation process to meet specific application requirements.

Kuaike's precision alloy products have been sold all over the world and have important applications in electronics, automobiles, medical care, energy and other fields. The production and sales center of Kuaike covers an area of 5,000 square meters and has more than 30 types of precision alloys that meet customer needs. In terms of industrial chain integration, the company maintains close cooperation with downstream end users to optimize the cost structure and enhance overall competitiveness.

Kuaike ensures that all kinds of user needs are guaranteed while improving efficiency and quality. We will also visit users regularly to understand their satisfaction and changes in needs, optimize service processes through data analysis, and reduce users' maintenance and time costs to improve cost performance. Transparent service process allows users to understand the service progress in real time through the online platform, improving user experience.

Copyright © Kuaike Precision Alloy (Shanghai) Co., Ltd. All Rights Reserved