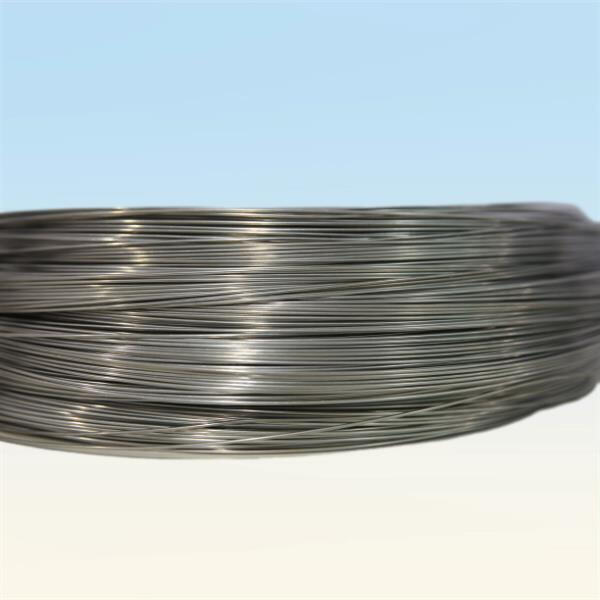

Mig wire for welding nickel is a specific type of wire that is very useful. This is made out of a kind of metal called nickel, which is strong and tough like this. One of the benefits of using

The other great benefit of nickel MIG wire is that they are very rust resistant. Rust occurs when metal is exposed to moisture or to such things as air and water. When that occurs, the metal can degrade and become unappealing to look at.

Nickel MIG wire is also great choice if you are shooting for professional finish for your welding projects. This wire can produce very

The use of nickel MIG wire can also help your welding skills. The wire is super flexible so you can use it on a variety of projects.

Overall, nickel MIG wire can allow you to give it a shot and taste how well it performs for your projects. Whether you're a beginner or an

Kuaike ensures that all kinds of user needs are guaranteed while improving efficiency and quality. We will also visit users regularly to understand their satisfaction and changes in needs, optimize service processes through data analysis, and reduce users' maintenance and time costs to improve cost performance. Transparent service process allows users to understand the service progress in real time through the online platform, improving user experience.

The precision alloy products provided by Kuaike can maintain stable performance under various conditions, and its excellent quality can reduce the cost of frequent replacement by users. Our precision alloy products have special magnetic properties, electrical properties or thermal expansion coefficients, which are suitable for high-precision and high-sensitivity applications, and can also be optimized by precisely controlling the preparation process to meet specific application requirements.

Kuaike's precision alloy products have been sold all over the world and have important applications in electronics, automobiles, medical care, energy and other fields. The production and sales center of Kuaike covers an area of 5,000 square meters and has more than 30 types of precision alloys that meet customer needs. In terms of industrial chain integration, the company maintains close cooperation with downstream end users to optimize the cost structure and enhance overall competitiveness.

Provide a professional technical support team to help users solve technical problems, conduct innovative designs, and produce diversified and personalized products to ensure that user needs are met. We plan to combine precision alloys with other materials to improve the comprehensive performance of materials, and reduce energy consumption and pollution in the production process by optimizing alloy composition and preparation process.

Copyright © Kuaike Precision Alloy (Shanghai) Co., Ltd. All Rights Reserved