Nickel resistance is a type of material that lasts quite a long time when exposed to very high temperature and heavy current. Its unique capability makes it highly useful for the production of critical things like electrical components and heating parts. In this article, you are going to learn what nickel resistance is, why it is important and how it can make a difference in different devices.

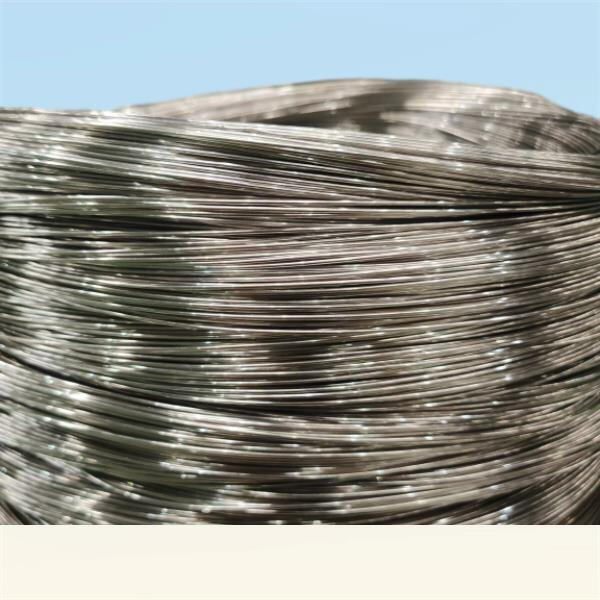

Nickel Resistance of Kuaike Precision Alloy is an alloy of nickel and other metals which is a strong material. This combination makes it unique, giving it properties that help keep it up in the face of high heat without breaking down. It is also difficult to influence when the electricity is flowing. Nickel resistance can be utilized in areas where there are abundant amounts of heat or electricity, such as electrical circuits and heating systems. These nickel chromium properties make it a material of great value in a wide range of applications.

Four major characteristics, flicker resistance, were included in the importance of making sure electrical parts work properly and safely. Nickel resistance wires do not heat up too much or get tired when current travels (labour) through them. This is important because it helps to ensure that electrical devices remain perfectly safe and function properly. Without nickel chrome alloy, circuits can burn out and cause dangerous issues such as fires or malfunctions. Hence, the resistance against nickel is critical to the safety and operability of many devil electrical tools we use daily.

Machines in large factories and industries are simply running at high temperatures every day. This is tricky, since heat can make machines fail or sputter. These machines utilize nickel resistance to keep everything running smoothly. Kuaike Precision Alloy Nickel resistance industries can enable acceleration without overheating and ensures that the machines can be used without damaging. Not only will this help to keep the machines in operation for longer, nickel chromium wire will save companies both time and money by preventing costly repairs and replacements. Nickel resistant material is an important factor that enables efficient working of industries.

Heating elements generally play a role in common household appliances such as ovens, toasters, or even some specific kinds of heaters. These heating elements have to withstand extreme heat while cooking or toasting food. These products of heating parts are made of nickel-resistant material which is made to resist a good amount of temperature. Such parts that are used in a tube or cavity-style heating elements would be subjected to nickel resistance which improves the unit life immensely and can be used with non-stop working operations without getting worn out. Such durability increases the appliances' reliability and guarantees their proper functioning for the day-to-day. As a result, being able to use wire nickel means knowing they will serve us right, give us more comfort, and have a long useful life, thanks to their nickel resistance.

For engineers, nickel resistance is a material they make use of in a wide variety of products they'd like to optimize the performance of. Widely used in designs to guarantee that different devices operate properly in harsh conditions, it is yet another one of these methods. Nickel resistance is typically employed in sensors, resistors, and so forth. These components need to function reliably in the face of extreme heat or electrical stress. Moreover, resistance to nickel corrosion is significant in sectors such as aerospace and automotive, where parts must endure high temperatures and hostile environments. Nickel resistance by Kuaike Precision Alloy is used to design engineers within value added products.

Provide a professional technical support team to help users solve technical problems, conduct innovative designs, and produce diversified and personalized products to ensure that user needs are met. We plan to combine precision alloys with other materials to improve the comprehensive performance of materials, and reduce energy consumption and pollution in the production process by optimizing alloy composition and preparation process.

Kuaike's precision alloy products have been sold all over the world and have important applications in electronics, automobiles, medical care, energy and other fields. The production and sales center of Kuaike covers an area of 5,000 square meters and has more than 30 types of precision alloys that meet customer needs. In terms of industrial chain integration, the company maintains close cooperation with downstream end users to optimize the cost structure and enhance overall competitiveness.

The precision alloy products provided by Kuaike can maintain stable performance under various conditions, and its excellent quality can reduce the cost of frequent replacement by users. Our precision alloy products have special magnetic properties, electrical properties or thermal expansion coefficients, which are suitable for high-precision and high-sensitivity applications, and can also be optimized by precisely controlling the preparation process to meet specific application requirements.

Kuaike ensures that all kinds of user needs are guaranteed while improving efficiency and quality. We will also visit users regularly to understand their satisfaction and changes in needs, optimize service processes through data analysis, and reduce users' maintenance and time costs to improve cost performance. Transparent service process allows users to understand the service progress in real time through the online platform, improving user experience.

Copyright © Kuaike Precision Alloy (Shanghai) Co., Ltd. All Rights Reserved